Sausage manufacturing combines art and science, producing delicious products enjoyed worldwide. The process involves transforming raw ingredients into flavorful sausages through various steps, from sourcing materials to packaging the final product. Understanding this intricate process can give consumers a greater appreciation for their favorite sausages and the craftsmanship involved.

In a factory setting, sausage manufacturing is primarily focused on efficiency and consistency. Industrial processes utilize advanced machinery that allows for high-volume production while maintaining quality standards. From traditional recipes to innovative flavors, the production methods have evolved significantly over the years. With a mix of traditional techniques and modern technology, manufacturers strive to deliver delicious sausages that meet consumer demands.

Let’s dive deeper into the ingredients and raw materials that form the backbone of sausage production.

Ingredients and Raw Materials

Creating high-quality sausages starts with selecting the right ingredients and raw materials. The choice of ingredients not only impacts flavor but also affects texture, color, and overall quality. Here’s a breakdown of the key components involved in sausage manufacturing:

- Meats: The primary ingredient in most sausages, meats can vary from pork, beef, chicken, and even specialty options like venison or lamb. Here are some common types:

- Pork: Known for its fat content, which adds flavor and moisture.

- Beef: Offers a robust flavor, often used in combination with pork.

- Chicken/Turkey: Leaner options that appeal to health-conscious consumers.

- Fat: Essential for flavor and juiciness, fat can come from the meat itself or additional sources like pork back fat.

- Spices and Seasonings: These are crucial for taste. Common choices include:

- Salt: Enhances flavor and acts as a preservative.

- Black pepper: Adds a subtle heat.

- Garlic: Provides an aromatic depth.

- Herbs: Such as thyme or oregano for added flavor profiles.

- Binders: Ingredients like breadcrumbs, starches, or proteins can help bind the sausage mixture together, ensuring consistency.

- Casings: Sausage casings can be natural (animal intestines) or synthetic (collagen or cellulose). They hold the sausage together during cooking and give shape.

Each ingredient plays a pivotal role in the final product. The balance of these elements defines the sausage's flavor, texture, and overall quality, making ingredient selection a critical part of the manufacturing process.

Also Read This: Building a Rewarding Career with Lifeguard Courses

The Industrial Sausage Production Process

Making sausages in a factory setting is a fascinating blend of tradition and technology. The industrial sausage production process involves several key steps that ensure efficiency, consistency, and quality. Let's break it down!

- Meat Preparation: The first step involves selecting and preparing the meat. This could be pork, beef, chicken, or a mix. The meat is cut into smaller pieces to facilitate easier grinding.

- Grinding: The prepared meat is then ground using industrial grinders. The size of the grind can vary based on the type of sausage being produced. For example, a coarse grind is often used for bratwursts, while a fine grind is typical for bologna.

- Mixing: Once ground, the meat is mixed with spices, curing agents, and other ingredients like ice or water. This step is crucial for flavor and texture. Automated mixers ensure that the mixture is uniform.

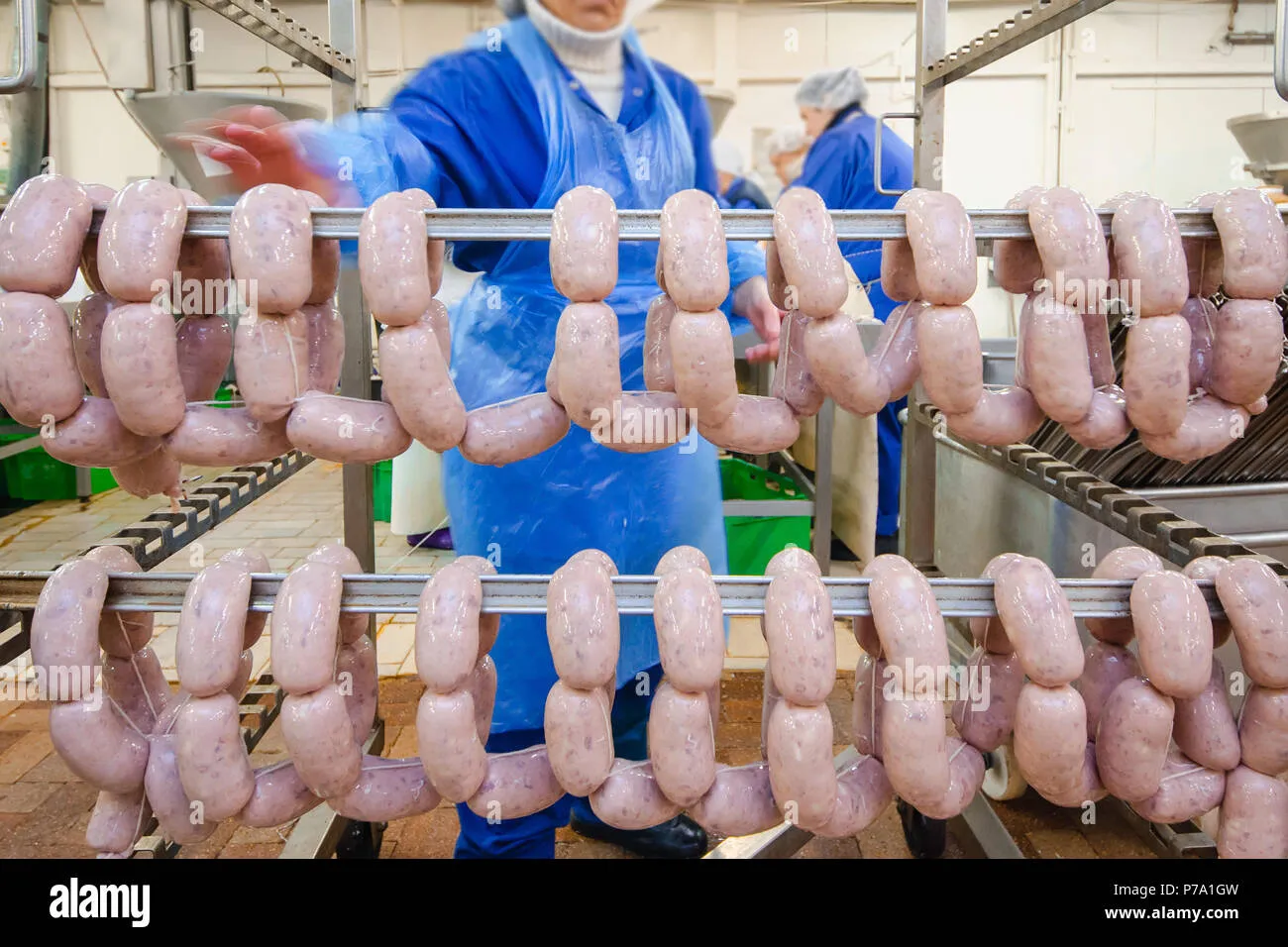

- Stuffing: The blended mixture is then stuffed into casings. This can be natural casings (from animal intestines) or synthetic ones. Industrial machines perform this step swiftly and efficiently, creating uniform sausage links.

- Cooking or Smoking: Depending on the type of sausage, they may be cooked or smoked. This step not only enhances flavor but also helps in preserving the sausage.

- Packaging: Finally, the sausages are cooled and packaged. Vacuum sealing is common to ensure freshness and extend shelf life.

This entire process is designed to maximize efficiency while maintaining high standards of quality and safety.

Also Read This: A Comprehensive Guide to Downloading Adobe Stock Photos

Quality Control Measures

Quality control in industrial sausage production is paramount to ensure the safety and satisfaction of consumers. Implementing rigorous quality control measures helps to maintain consistency and prevent contamination. Here are some essential practices:

| Measure | Description |

|---|---|

| Ingredient Inspection | All raw materials undergo strict checks for quality, ensuring that only the best ingredients are used. |

| Hygiene Standards | Factories must adhere to stringent hygiene protocols to prevent contamination. This includes regular cleaning and employee training. |

| Temperature Monitoring | Maintaining the correct temperatures during processing and storage is crucial. This helps minimize bacterial growth. |

| Batch Testing | Samples from production batches are frequently tested for flavor, texture, and microbial safety to ensure consistency. |

| Traceability Systems | Implementing traceability allows for tracking products back to their sources, which is vital in case of a recall. |

By integrating these quality control measures, sausage manufacturers can deliver delicious and safe products that consumers can trust.

Also Read This: Understanding Rumble Boxing Class Costs and Advantages

5. Packaging and Distribution of Sausages

Once sausages are produced, the next crucial step in the industrial process is packaging and distribution. This phase ensures that the sausages maintain their quality and freshness from the factory to the consumer's table. Let’s break it down!

Packaging: The packaging of sausages is not just about aesthetics; it's essential for preserving flavor, texture, and safety. Here are the common packaging methods:

- Vacuum Sealing: This method removes air from the package, which helps prevent spoilage and freezer burn. It’s great for extending shelf life.

- Modified Atmosphere Packaging (MAP): In this technique, the air inside the package is replaced with a gas mixture that slows down spoilage while keeping the product fresh.

- Plastic Casings: Some sausages are packaged directly in plastic casings, which can be heat-shrinked for a tight fit, reducing microbial growth.

Once packaged, sausages are labeled with vital information such as expiration dates, nutritional details, and cooking instructions. This transparency helps consumers make informed choices.

Distribution: The logistics of getting sausages from the factory to stores involve several steps:

| Step | Details |

|---|---|

| Cold Storage | After packaging, sausages are kept in cold storage to maintain quality. |

| Transportation | Special refrigerated trucks are used to transport the sausages to various retailers. |

| Retail Display | Sausages are displayed in refrigerated sections, ensuring they remain at safe temperatures for consumers. |

6. Conclusion and Key Takeaways

In conclusion, the industrial process of making sausages is a fascinating blend of art and science. From the selection of quality ingredients to the meticulous steps of mixing, stuffing, cooking, and finally packaging, each stage plays a pivotal role in delivering that delicious sausage to your plate.

Key Takeaways:

- Sausage production involves several stages, each requiring specific techniques and equipment.

- Quality control is paramount at every step to ensure food safety and taste.

- The packaging not only preserves the product but also informs consumers.

- Efficient distribution systems are essential for delivering fresh products to retailers.

Understanding this process not only enhances our appreciation for sausages but also sheds light on the complexities of food production in our modern world. Next time you enjoy a sausage, you’ll know the journey it took from factory to fork!