Coca-Cola is more than just a beverage; it's a global phenomenon. Understanding its production process reveals the intricate steps involved in creating that iconic taste we all love. From sourcing raw ingredients to the final bottling, each phase is meticulously crafted to ensure consistency and quality. This behind-the-scenes look into Coca-Cola's production showcases not only the technology and innovation but also the dedication to delivering a refreshing experience to millions worldwide. Let’s dive deeper into this fascinating world!

The Ingredients that Make Coca-Cola

The magic of Coca-Cola lies in its unique blend of ingredients, each playing a crucial role in achieving its distinctive flavor. Here’s a closer look at the key components:

- Carbonated Water: The primary ingredient, providing the fizzy sensation that many crave.

- Sucrose or High Fructose Corn Syrup: This sweetener is essential for delivering that signature sweetness.

- Caffeine: A natural stimulant, caffeine adds a kick and enhances flavor.

- Phosphoric Acid: This ingredient gives Coca-Cola its tangy flavor while also balancing sweetness.

- Natural Flavors: The precise combination of secret ingredients, including various plant extracts, contributes to Coca-Cola's unique taste. This is where the magic happens!

- Caramel Color: Not just for aesthetics, this ingredient gives Coca-Cola its rich brown hue.

Each ingredient undergoes rigorous quality checks and sourcing standards, ensuring that every sip of Coca-Cola is consistent and satisfying. It's this harmonious blend that keeps fans coming back for more, making Coca-Cola a timeless classic in the beverage industry.

Also Read This: Royal Rumble 2023 Date Event Highlights and Results

The Manufacturing Process Explained

The production of Coca-Cola is a fascinating blend of art and science. It all starts at the syrup manufacturing stage, where the secret formula is combined with water, sweeteners, and flavorings to create the iconic concentrate. This syrup is then transported to bottling plants around the world. Here’s a breakdown of the key steps involved:

- Water Purification: The first step involves purifying water, which is the main ingredient in Coca-Cola. Advanced filtration and purification technologies ensure that the water meets the highest quality standards.

- Syrup Preparation: The secret syrup formula is mixed with the purified water and sweeteners. This mix is blended to perfection, ensuring that every drop tastes just right.

- Carbonation: Once the syrup is ready, carbonation is introduced. This process involves infusing the liquid with carbon dioxide under pressure, giving Coca-Cola its signature fizz.

- Filling and Capping: The carbonated beverage is then filled into bottles or cans. Automated machinery ensures that every container is filled accurately, followed by capping to maintain freshness.

- Labeling and Packaging: After capping, each bottle or can is labeled and packaged for distribution. This step not only identifies the product but also promotes brand visibility.

Each of these steps is meticulously controlled to ensure that every bottle of Coca-Cola tastes just as delightful as the last. The attention to detail in manufacturing is what keeps fans coming back for more!

Also Read This: Behance code viewing tutorial

Quality Control Measures in Coca-Cola Production

Coca-Cola takes quality control very seriously, ensuring that every product leaving the production line meets its high standards. Here are some crucial quality control measures in place:

- Raw Material Testing: Before production begins, all raw materials, including water, sweeteners, and flavorings, undergo rigorous testing to ensure they meet Coca-Cola's stringent quality standards.

- In-Process Checks: Throughout the manufacturing process, regular checks are conducted. This includes monitoring the syrup concentration, carbonation levels, and filling accuracy to catch any discrepancies early on.

- Microbiological Testing: To ensure the safety and quality of the beverage, microbiological tests are performed at various stages of production. This helps detect any potential contamination.

- Final Product Testing: Before packaging, samples of the finished product are rigorously tested for taste, appearance, and carbonation levels. Only those that meet the brand's standards are approved for distribution.

- Feedback Loop: Coca-Cola encourages consumer feedback, which is analyzed and used to improve products continuously. This responsiveness to customer tastes helps maintain quality over time.

Through these comprehensive quality control measures, Coca-Cola ensures that each sip is not just refreshing but also safe and consistent, reinforcing its position as a global leader in the beverage industry.

Also Read This: How to Cite a Photo from Getty Images for Your Research Papers and Publications

The Role of Packaging in Coca-Cola's Success

Packaging plays a pivotal role in Coca-Cola’s success. It’s not just about protecting the product; it’s about creating an emotional connection with consumers. The iconic red and white branding is instantly recognizable, and the innovative design of bottles and cans makes them stand out on the shelves. Let’s break this down further:

- Brand Recognition: The classic Coca-Cola script and color scheme are so well-known that they evoke feelings of happiness and nostalgia. This instant recognition helps boost sales and engenders loyalty.

- Functional Design: Coca-Cola invests in research to ensure its packaging is not only attractive but also functional. For example, the contour bottle was designed for easy gripping and has become a symbol of the brand itself.

- Environmental Considerations: In recent years, Coca-Cola has made strides to use recyclable materials and reduce plastic waste. For instance, their PlantBottle is made from up to 30% plant-derived materials, showcasing their commitment to sustainability.

Packaging innovations, like the introduction of smaller cans and eco-friendly options, cater to changing consumer preferences. By focusing on packaging, Coca-Cola ensures that its products are not only appealing but also meet the demands of a modern, environmentally-conscious consumer.

Also Read This: Understanding High Definition Rumble Features

Distribution and Logistics of Coca-Cola

The distribution and logistics of Coca-Cola are nothing short of impressive. With a global presence in over 200 countries, the company has mastered the art of getting its products to market efficiently. Here are some key aspects:

| Aspect | Description |

|---|---|

| Supply Chain Management | Coca-Cola employs a sophisticated supply chain that allows them to source ingredients from various locations and ensure timely production. |

| Distribution Network | With a mix of direct store delivery, warehouse delivery, and fountain delivery, Coca-Cola can reach retail partners and consumers effectively. |

| Technology Integration | Advanced tracking systems and data analytics help optimize routes and reduce delivery times, ensuring fresh products reach customers. |

| Collaborations | Coca-Cola’s partnerships with local bottlers enhance their ability to adapt to regional demands and preferences. |

In essence, Coca-Cola’s logistics are designed to be agile and responsive, which is crucial for maintaining its position as a leader in the beverage industry. This efficient distribution model ensures that whether you're in a bustling city or a remote village, you can enjoy a refreshing Coke at any time!

Inside the Production Process of Coca-Cola on Dailymotion

The production process of Coca-Cola is a fascinating journey that transforms raw ingredients into one of the world's most recognizable beverages. The process involves several key stages, each meticulously designed to ensure quality and consistency.

Here is an overview of the primary steps involved in the production of Coca-Cola:

- Ingredient Sourcing: The process begins with the selection of high-quality ingredients, including carbonated water, sugar (or high fructose corn syrup), caffeine, natural flavors, and caramel color.

- Mixing: In this phase, the ingredients are precisely measured and mixed to create the syrup that forms the base of Coca-Cola. This step is crucial, as it defines the beverage's unique flavor profile.

- Carbonation: The syrup is then combined with carbonated water, which adds the signature fizz that Coca-Cola is known for. This step requires careful control of pressure and temperature to achieve the perfect carbonation level.

- Quality Control: Throughout the production process, stringent quality control measures are implemented. Samples are taken at various stages to ensure that the product meets Coca-Cola's high standards.

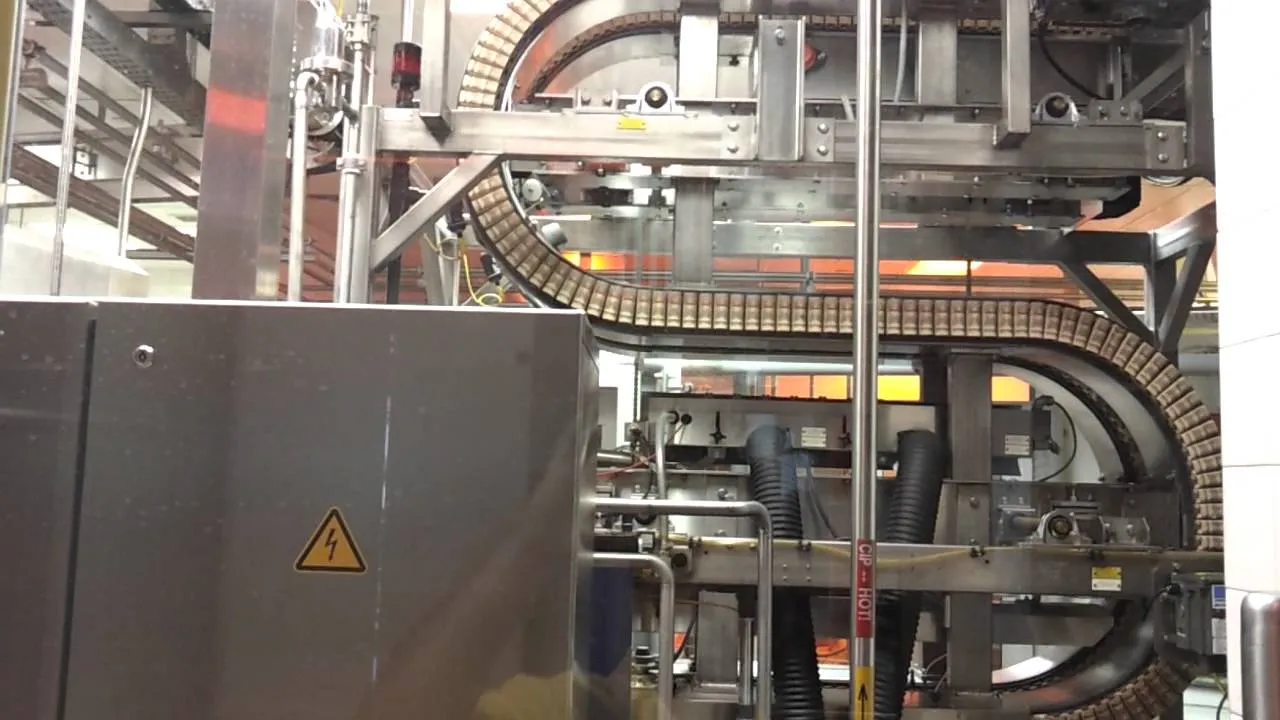

- Bottling: Once the mixture is complete, it is bottled or canned. This stage involves advanced machinery that fills, seals, and labels the containers efficiently.

- Distribution: Finally, the packaged beverages are distributed to retailers and consumers worldwide, ensuring that Coca-Cola is available in various locations.

In conclusion, the journey of Coca-Cola from factory to consumer is a testament to the brand's commitment to quality and consistency, showcasing the intricate processes that transform simple ingredients into a beloved beverage enjoyed by millions globally.